The increasingly rapid advancement of technology that we are all

becoming subject to permeates every niche of our existence.

Whether this is necessarily good or bad is up to the individual to decide,

but when it eats its way into a craft which is essentially primitive in nature, it can

only be described as detrimental. Generally, potters in

the West have always directed and controlled the

processes of their craft rather than worked with their

materials in the directions to which they naturally tend.

Now we are reaching a very dangerous stage whereby

craft pottery can either plunge into a sterile

technological environment or return, probably and

sadly too, out of economic necessity rather than the

aesthetic, to its roots. The advent of electricity, gas and

to a certain extent oil, has turned the most creative part

of the potters processes into a mere finishing tool, a

method of mediocrity whereby pots are made

permanent in much the same way as plaster sets in a

mould. Indeed, one can now obtain automatic firing

devices, it has to be wrong to make pots by hand and

then to fire them using computers. Bernard Leach in 'A

Potters Book' wrote, 'There are people who imagine

they can play at potting, condescending in their opinion

from fine art to a craft which they can expect to learn in a

few weeks or months, buying everything ready made

and avoiding drudgery by mechanical devices. Pottery is

still being made and decorated under this mis-

conception, it would be well for both potter and public

to realise that the results of such performances look

precisely what they are, unhappy exhibitions of

dilettantism in a mechanical age'.

The potter has essentially three elements upon which

to bestow his creative powers, those of clay, glaze and

fire, but at the same time he must strive to be true to

these three. For example, if he makes his pots from clay,

they should be seen to be made from clay, it is no good

making a pot as though it were turned from metal. As

potters we have this amazing potential to deviate from

the perfectly symmetrical, even on the wheel. There is

far too much emphasis put on what goes into a glaze,

than what a glaze can do, and likewise with kilns and

firing them. A live flame, especially if it originates from

burning wood, can be used in such a way as to make

formal decoration superfluous if not unnecessary. I have

heard of wood firing and its dramatic effects being

dismissed as an easy alternative, a way of decorating

without decorating, however, if it is used in the same

way as a brush and pigment it is incredibly demanding

physically, mentally and in terms of accumulating

knowledge. One can see what is happening with a brush

and pigment, it is controlled. One cannot see what is

happening inside the kiln, but it is possible to have a

pretty good idea. The following account consists of

knowledge gained largely from hard won experience,

very little is gleaned from published descriptions of

others. While at Farnham, like most other students in an

art college, I had the unique opportunity to be totally self

indulgent-digging holes in the hillside and firing them was my main pre-occupation!

To commence we must go back in time, to when

wood was the only fuel for firing pots, to Japan during

the period from the eleventh to the fourteenth

centuries. The only active ceramic producing localities

during this period became known as the Six Ancient

Kilns, three of these being Bizen, Tamba and Shigaraki.

The early wares from these kilns were fired in a kiln

called the Anagama, or cave kiln. This was simply a tunnel

in the hillside. The location of the kiln was determined

by a favourable land contour and suitable soil

conditions. A sandy soil with a percentage of clay and

no rock was necessary. Limestone or shale in the kiln

wall would upset the stability of the kiln during firing,

and naturally a compact soil was necessary in order for

successful digging to occur. This simple anagama,

usually six to ten feet long, fulfilled all the essential

elements of any kiln. A firemouth for wood burning, a

chamber in which to place the wares and to accumulate

heat, and a flue for the exit of exhaust gases. In this

upward kiln the gases moved by convection, and at the

same time produced enough draught for the rapid

combustion of wood.

Once fired, the kiln was sintered to a hard surface and

became self supporting. The more firings it had the

stronger it became. Long firings were necessary largely

due to the dampness of the earth, the kilns took several

days to reach 1300, fired on cypress and pinewood

which was locally abundant. It took many hours of firing

to drive off the water in the walls of the kiln chamber.

Until the kiln was quite dry, no build up of heat could

take place. Temperature gauging was carried out by eye

which resulted in variations between firings. As a result

of the firing process the pots had rich surfaces, colours

and texture, resulting entirely from the firing, rather

than from the design. The passage of flames through the

setting of the kiln gave random colouring and qualities

to the wares. The most important feature of these pots

was natural ash glazing, the deposit of ash being the

inevitable result of the placement of the pots in the kiln

and the firing cycle. The ash, the by-product of the

burning wood flies through the kiln following the flame

path, thus settling on the pots, and melting to form a

glaze when sufficient temperature has been attained.

The success of ashing was dependent on the fusibility of

the ash and on the length of the firing. Conifers, such as

cypress and pine are especially fusible, and only an

extended period of firing would generate sufficient ash.

The position, extent and the flow of ash was dependent

on the placement of the pots in the kiln, the duration of

the firing, and the temperature achieved. Together with

'flashing' from the flame, and ashing, the pots were also

enhanced by kiln particles, stacking scars (the pots were

simply stacked in the kiln) and packing deformation. No

other tradition has managed to capture so much beauty

from the firing process and at the same time done it with

such innocence. It was not the intention to use the firing

as a conscious means of decoration, it was quite simply

a means whereby the pots became able to perform their

preconceived functions. The main point is that from the

simplest of firing methods some extremely beautiful

pots were created. I cannot help feeling however that

somewhere amidst the battlefield of exhausted men and

piles of wood were potters who, like myself, really got

quite excited by what they were doing.

There are several well proven principles and designs

available for burning wood and firing pots efficiently,

however efficiency does not necessarily contribute.

towards promising pots, indeed quite the opposite. It is

perfectly possible to fire pots with wood using an

extremely efficient kiln and to end up with pots having

no evidences of wood firing upon them. The emphasis in

this case would be one of pure economics, wood as a

cheap fuel forgetting its decorative potential, although

it must not be forgotten that wood is also labour

intensive and requires considerable space and

management. The concern here is the use of wood in a

dynamic manner, not necessarily as efficiently as

possible.

The cross draught principle is logically the optimum

means to extract the most from the elements of wood

firing that are available. Flame and ash pass between the

pots throughout the length of the chamber; in a

downdraught kiln for example the flame passes past the

pots between the shelves, usually the only pots to

capture the excitement are the ones at the top of the

kiln. I have come across one kiln superior to the cross

draught in this respect and that is one belonging to

Takeshi Yasuda which has a flue exit consisting of a

hole in the centre of the kiln floor covered by a raised kiln

shelf. This appears to be an excellent method of

retaining the bulk of ash and dancing flames within the

kiln chamber.

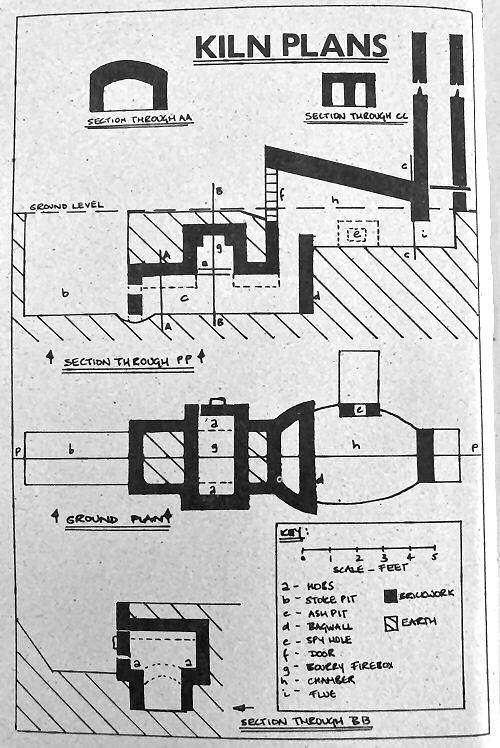

The kiln I built at Farnham turned out to be nothing

more than a sophisticated anagama. Through a

shortage of brick it was built into the ground on a slight

slope, the chamber floor being eighteen inches below

ground level and the ashpit floor four feet below. Having

the ashpit that much lower than the kiln chamber

produced a positive pressure principle, the opposite to

the negative pressure experienced in downdraught

kilns. The kiln chamber had the shape of an elongated

egg; from the outset I realized that a live flame naturally

following its shortest route to the exit from the kiln

would not take time to travel into corners. Thus the kiln

chamber, tapering towards the exit flue, was

constructed with the organic shape of the anagama in

mind. The end result was a kiln utilising both updraught

and cross draught principles, very similar to the draught

of the anagama. The walls of the firebox and ashpit

together with the chamber arch and door were built of

firebrick, the floors made serviceable with a 90% grog

10% clay mix. The chamber arch rose eighteen inches

above ground level at the front of the kiln tapering

downwards towards the flue. By far the best type of

firebox for the combustion of wood is the Bourry, a

system whereby the bulk of wood is burnt suspended

across the ashpit at right angles to the kiln with the ends

of the logs resting on two ledges called the hobs. Thus

the wood burns in mid air and maximum combustion

can take place. The ashes and embers fall into the ashpit

and provide a ready source of preheated secondary air.

With this type of firebox and an ashpit of some six feet in

length I was able to use the effects of flame and ash to

their maximum potential.

The firing of a wood kiln has to be an entirely separate

exercise from the rest of the process, the concern is no

longer with the individual pots, but with a device which

affects all of them together. The demands in terms of

concentration, usually some form of physical stamina

and an almost total reliance on intuition make it

inevitable that pressures of making pots and packing

them in the kiln are forgotten. The packing of the kiln is

the most crucial part of the whole process. It is here that

one decides, to a large extent, the fate of any one

particular pot. What actually happens inside the kiln is

not so much in control as the firing itself. One cannot

really predict the outcome, but it is possible to set things

up so that the so called 'accidentalism' aspect of wood

firing is to a certain extent, calculated. Packing the kiln

at Farnham, though only 25 cu. ft., could take as long as

a whole day. The same psychological problems are

experienced when packing as when decorating pots in a

formal manner, however there is a difference. While

packing a wood kiln one anticipates potential

decoration, it is not possible to see the end result until

the process is completed. Hours can be spent

deliberating where pots should go, rearranging them

and possibly throwing some away. It would take much

good fortune for me to be happy with the pack. It may

have been made too open or too tight or pots that I really

wanted in the best places would not fit.

There are several decorative processes to be

considered while packing. The path of burning gases

through the maze of pots is dynamically creative. This

has to be taken into account, for it carries with it a

natural glaze, that of flyash. It is important to decide

which part of the pot is to receive all this potential

activity, if at all, for expectations can easily be wrong..

The majority of flame will find its easiest route to the

exit, it will favour a large gap in preference to a smaller

one. It is possible, by way of the pack, and particularly

with the cross draught principle, to virtuallly tie knots in

the flame path. This is important because where the

flame, which is far hotter than the kiln temperature,

impinges on a pot, the extreme heat of that flame fluxes

the surface, or in more linguistic terms, causes flashing.

An alternating cycle of oxidation and reduction occurs

naturally in a wood kiln causing the fluxed, exposed

surface of the pot to become reddish, in contrast to the

greyness of the reduced body. Pots that are unglazed on.

the outside can be stacked on the top of, inside or next

to each other. Where they touch the surface cannot be

reoxidised and thus remain grey, or lighter in contrast to

the redness of the oxidised body. This aspect of

decoration is of major consideration while packing,

along with the positioning and size of wads, if used. The

function of wads is either to aid stacking (the use of kiln

shelves is minimal) or to prevent pots from sticking to

each other or to the kiln furniture. This is usually

necessary if high temperatures are attained, or if a lot of

ash is generated. 'Sticking scars' are quite acceptable

but it gets a bit much if pots have to be broken to get

them apart. Wads can be made of clay which leave grey

marks on the pot, or alumina mixed with china clay and a

little bentonite for plasticity. The alumina wads leave

conspicuous white marks, one alternative is to use

seashells which cause scarring on the pot wherever they

are placed. The calcium carbonate of the seashell forms

a eutectic with the silica and alumina of the clay body

and fuses, leaving a scar. The remainder, having been

reduced to quicklime (calcium oxide) in the firing is

easily removable. Additionally, the salt in the seashells

volatilises leaving pleasing marks on the surface of the

pot.

Major consideration must also be given to flame

pattern. In anticipating the path of the flame through

the kiln it is important to remember that the flame will

always follow its easiest route to the exit. Obviously, I

can only speak in detail regarding the kiln described

here, however the criteria should be easily applicable to

any other. Bearing in mind the shape of the chamber and

the cross draught element, if a bagwall is built, be it only

three bricks high, the flame is immediately forced to the

roof of the kiln. Unless there is a large gap in the middle

of the chamber, the flame will then run the length of the

chamber at roof height and drop down to the flue at the

back. The pots in this path tend to be high fired, heavily

reduced and with the bulk of the ash falling on the pots

at the back. The remainder of the kiln, the middle and

bottom front is usually cooler and comparatively pale in

colour. A small bagwall is necessary however to prevent

the flame from travelling along the kiln floor to the flue. I

have experimented with the positioning of large pots,

when packed in the kiln with the pots of more

conventional size. It is not really practical to have one

large pot at the back, for the part of it nearest the flue

tends to be lower fired than the rest of it. Nor is it

practical to place one pot off centre in the middle for this

upsets the flame currents and causes unevenness not to

mention the phsyical problems when packing the space

next to it. Two large pots right at the front will restrict

the flow of flame and ash to such an extent as to make

the firing one big headache. By far the best position on

all counts is to have one large pot right at the front in the

middle. This automatically splits the flame creating two,

major flame paths within the kiln. This in turn creates

greater kiln potential. Firstly and inevitably the ashing

on this large pot can be very interesting, Secondly, the

two flame paths eventually have to converge at the flue,

if not before, and under these conditions, fire flashing

and ashing are at a maximum. It is important to consider

the effect that pots, or stacks of pots in certain

positions, will have on this flame path. With a little

cunning, a maze of eddies can be conjured up, the more

corners the flame has to navigate within the pots, the

greater the flashing. If more ash is desired on some pots

than others these should be packed more loosely than

the rest and in such a position as to be in the anticipated

flame path.

There are many things then to contemplate while

packing. It is at this point that the last say is said, the last

direct influence on the pots carried out. From here on,

although the kiln is to a large extent controlled, it is the

kiln that dictates the final outcome, however this is

influenced by many prevailing factors, some of which

may cause one firing to be completely different from the

next. At this stage the kiln and the firing speak for

themselves but always in close relation to these things.

Half the enjoyment, half the excitement is in the

unpredictability of it all, not knowing whether there will

be but one good pot. The final outcome can be entirely

transformed by the length of the firing, the type of

wood, the amount of moisture in the ground,

atmospheric pressure, the weather and a whole host of

other factors. Indeed, the only explanation I could offer

for a kiln full of orange coloured pots of a tone I never did

achieve again was that on the day of the firing it was

ridiculously hot and atmospheric pressure was much

higher than normal.

It is important after packing and bricking the door to

pause and contemplate what is to come. The right

mental attitude is essential, for many things can cause

the firing to go wrong, half of them directly affecting the

firer. The weather and time of day are the most

influential elements upon morale, not to mention the

effect on the duration of the firing and the atmospheric

conditions within the kiln. Twenty four hour firings

include the night. Rain during the day is bearable, rain at

night, particularly if heavy, can dampen the most

enthusiastic of spirits. The dread of a stormy night is a

force to be reckoned with. High winds are capable of

reversing the kiln, of blowing the chimney down. They

can alter the pull of the chimney drastically, and can

make chaos of controlled stoking. Rain soaks wood, the

ground becomes wet and boggy, the firer becomes wet

and cold, then hot and sweaty, then wet and cold again

as each stoke is repeated. The most difficult hours to

contend with are those preceding dawn. Those first

signs of daylight are such a boost to flagging spirits and

an exhausted body-but they take such a long time to

appear.

A little fire during the evening is a fitting end to the

days packing. This will thoroughly warm the kiln and dry

out any remaining moisture. It is difficult however to

stop and retire home to bed, preferably early. It is

essential I think to start before dawn the next morning,

there is something unique about those first silent wisps

of white smoke mingling with a fresh day. The birds

wake, the dew gleams on the trees, and the little fire

crackles merrily. Such a small fire and so relaxing, yet

warm enough to sort out cold fingers in the winter.

Breakfast is next, but it is short, the magic of the first

few hours, they soon pass. The fire begins to rage, the

flames pour along the firebox floor like a waterfall and

work begins in earnest. Wood must be sorted and

bundled for each stoke, the firebox must be raked

regularly in order to keep all the wood burning, and

wood must be stoked into the kiln with relentless

regularity. It is difficult however in the early stages to

overcome the temptation to force an excess of

temperature against time. For myself, I am sure it has

something to do with the desire to exert the most violent

conditions possible, short of disintegration, upon the

pots. It is satisfying to know that they survived, to know

that they have been subjected to their limits, to their

utmost physical tolerance. To actually see the scars of

flames and the distortion of form satisfies me in the

same way as being able to see that a pot has been made

by taking the clay to its utmost physical capacity. In the

same way, the materials used and the method of firing

impose limitations on what can be made. Coarse clay

will not allow delicate forms, and delicate forms will not

survive excessive kiln conditions. Thus, from a given set

of limitations a distinctive style will emerge. Similarly,

one can take the firing to such a point where the

limitations of the materials begin to take effect, this is a

distinctly creative part of the process. It is a point of

marginal plasticity, when pots with certain forms and

inbuilt weaknesses, stacked in a particular manner will

almost certainly distort. The glazes used are in such a

molten state that they are running down the sides of the

pots, flyash is spontaneously fusing to them and if

enough has accumulated is behaving in a similar

manner. This part of the firing, accounting for a heat

tolerance of no more than ten degrees centigrade, is a

sensitive period. It can be approached with caution, or

with rapidity, it can be frozen by immediate cooling. The

critical factor is when to stop. It is handy to have a

spyhole with a specimen pot in view, so one can watch

and wait for the right moment, to be able to see the

extent of distortion and how far the glaze has run.

Wood varies in calorific value and heat worth from

species to species. Softwoods, especially of the

coniferous type have a greater calorific value then

hardwoods. They also contain a greater resin content,

resin being highly flammable. Another factor of

softwoods lies in their lower specific gravity and more

open texture, which exposes more surface per unit of

weight thus speeding combustion. All this is important

to remember, during firing it usually results in equal

amounts of thin softwood and thick hardwood being

used. Thin wood will provide the immediate release of a

lot of energy, resulting in rapid temperature rise,

whereas thick hardwood will provide mainstays in the

firebox for long periods of time and also promote a slow

but even release of heat. The type of wood used during a

firing can have a marked effect on the atmosphere

within the kiln, and is also influential in the colouring of

ashing. If a lot of pine is burnt, ashing tends to be very

fluid and light green, hardwood will promote drier

ashing and tends to be yellowish. Pine can produce the

most violent of reducing conditions, also great

quantities of black smoke, this sight however is not

necessarily indicative of good reduction. Whatever the

type of wood used, it must be thoroughly dry before it

can realise its maximum heat potential. To fire a kiln with

damp wood is a futile waste of effort, for dampness will

consume at least half the available heat energy in being

driven off. Likewise freshly felled wood will require two

or three years to dry out, and will then still maintain a

water content of some twenty per cent. Even this will

use up a third of the energy available.

Briefly, wood burns in two stages. The first stage of

burning is the combustion of volatile gases driven out of

the wood during the charring process. If one watches

the wood as it is placed in the firebox, it is literally roasted.

The gases pour visibly out of the wood and these ignite

spontaneously even before the wood itself starts to burn

The resin content of the wood plays an instrumental part

here, the greater the resin content the greater the heat

release during this initial stage of combustion. As gases

are being burnt, longer flames are produced. Above

eleven hundred, this part of the burning process will

produce immense flames. As the wood continues to

burn these will gradually recede as the flame length

diminishes and the wood takes on a more steady rate of

heat release. Droplets of resin are also driven out of the

wood, these do not ignite until they have found

sufficient oxygen to do so, usually in the kiln chamber

rather than in the firebox. The second stage of

combustion is from the non volatile part of the wood,

charcoal, in the form of embers. This burns with a

shorter flame, so that heat release is more localised. The

charcoal requires oxygen to burn, and as the bed of

embers in the ashpit builds up the oxygen requirement

for efficient combustion increases in proportion. After a

point, the embers may use up so much oxygen that the

volatile gases cannot burn and pass through the kiln

without releasing energy. In this case, as I have

experienced many a time, usually through a desire for

entertainment rather than substandard firing technique,

an enormous roaring fire of combustion will light up the

whole kiln site, something comparable to near daylight.

The ideal, naturally, is to have the gases buring inside

the chamber, usually achieved when a soft flickering

tongue of flame is issuing gently out of the chimney.

Under these circumstances, unless heavily reducing,

the kiln should be gaining temperature.

However well dried the pots and the kiln are, it is

essential to start slowly. A small campfire for an hour or

so followed by a large campfire for another hour or so

will ensure a slow temperature rise of up to two

hundred. Another two or three hours up to six hundred

is recommended. Anything much faster than this,

though it may not cause disintergration of pots, some

cracking and partial splitting of the clay surface may

occur. Over this period the size of the fire in the ashpit is

progressively increased in size until around six hundred

when wood can be stoked in from the Bourry

firebox door, so that it lies at an angle, with one end in

the ashpit and the other resting on the hobs. It is

important to criss cross the wood as much as possible

so that maximum combustion is achieved by having a

maximum surface area of wood free burning. The

embers from this wood are allowed to accumulate

beneath the hobs in order to bring them up to red heat,

and thus to a point where stoking across the hobs can

commence. The temperature at this point is near to

that where reduction commences, around nine

hundred.

Reduction is achieved by one of two methods.

Inefficiently speaking, one can overstoke, that is

feeding an excess of fuel into the firebox, which in turn

cannot be burned by the available oxygen. This causes

an excess of black smoke from the stack, a factor not

indicative of the state of reduction. It is merely a waste

of heat worth in the form of unburnt gases. Under these

conditions, temperature rise will cease, and in all

probability will fall.

The alternative, and by far the more efficient method

is to decrease the amount of oxygen per constant of

fuel, by closing up the secondary air vent of the ashpit.

Using this method, very little heat potential is wasted,

and although temperature may not rise, it will not fall.

This inevitably calls for an alternating oxidising and

reducing cycle, for under oxidising conditions,

temperature will rise rapidly. Therefore it is necessary to

be constantly aware of proportionate kiln atmospheres

and to react accordingly.

It took many firings for me to learn and understand the

functioning of the Bourry firebox. Temperature rise

after eleven hundred is difficult to achieve, and after

twelve hundred nigh on impossible unless a subtle,

understanding touch is available. Reduction, especially

if fierce, will almost inevitably cause. a drop in

temperature. In order to gain temperature it is necessary

to have a subdued oxidising flame. This flame, as it does

not carry any unburnt, cold fuel, is hotter than the kiln

will ever get, it can be seen as a slender white tongue

flicking into the kiln and dispersing before it reaches the

flues. Under these conditions it is possible to get a

temperature rise of up to forty degrees with one stoke,

though twenty degrees is a normal figure. Severe

reducing conditions with violent, rushing and long, yet

very desirable flames can drop the temperature as much

as sixty degrees, so one has to engineer the stoking so

that a staggered yet gradual rise in temperature is

achieved.

The embers in the ashpit, the by-product of wood

burning across the hobs, are instrumental in achieving

temperature rise. If the embers rise above a certain

volume, the supply of oxygen to the hobs is severely

reduced; it is being used up in burning away the embers,

therefore efficient combustion cannot take place and

temperature rise either stagnates or falls. If the bed of

embers falls below a certain volume, the air entering the

kiln by means of the secondary air port is insufficiently

preheated and causes similar effects regarding

temperature.

The method by which the volume of embers is

controlled is quite logical. If a lot of thin wood is burnt, a

lot of embers accumulate. This is because the thin wood

does not take long to burn through, and will do so before

the bulk of the wood is completely burnt, thus ending up

as embers in the ashpit. Larger logs are advantageous

for a more controlled firing. They take a long time to

burn through, at the same time giving a constant flame

to the kiln. Temperature rise is thus slower, but more

sustained. The embers that do fall in while the stoke is

burning, are sparse but continuous, and are constantly

being consumed with ease and a minimum of oxygen by

preheated secondary air. Thus when the stoke does get

to the point of collapse, there is sufficient combustion

space within the ashpit for the subsequent embers.

Also, if all has gone well, one will have gained twenty

five degrees, five more than the amount that will be lost

due to the violent, reducing flame caused by the embers

falling in (which causes a temporary, but excessive lack

of oxygen). This alternating between a soft oxidising

and a raging reducing fire is sufficient to produce well

reduced pots if maintained, and is also particularly

desirable for its range of colours on the raw clay body.

It is possible to fire for great lengths of time without

causing any large collapse of the stoke, at the same time

maintaining a constant reducing atmosphere and

temperature rise. This is done by periodically stoking

using two or three main supports of large logs covered

with thin pieces criss crossed on top until the firebox is

full. The large logs prevent the smaller wood from falling

in once burnt through, thus it will be free burning in mid

air throughout its entire combustion The large logs fall

in gradually and rarely all at once. Thus in between each

complete fresh stoke, it is possible to fit in two or three

stokes of thin wood on top. In addition to every fresh

stoke, the embers are raked through vigourously, this

keeps them turned and continually burning and

breaking down. In doing so vast quantities of flyash are

generated.

Raking through the embers to do this can be quite a

conscious exercise, and if this is done often enough and

long enough it can promote amounts of glaze on the

pots concurrent with several days firing, even though

the firing may only last twenty four hours or so. It is

important to arrange the pile of embers after raking, just

inside the entrance to the ashpit, and just before the

hobs. This accounts for maximum preheating of the

secondary air, and leaves a clear space underneath the

hobs for the passage and easy combustion of the flame

and gases.

Thus it is quite feasible to control the rate of

temperature rise, and also the ratio of oxidising and

reducing flames, this factor alone is capable of causing

one firing to be completely different from the next.

One would automatically assume that due to

increasing stoking skill and efficient use of wood the

length of the firing cycle would diminish. This was not

the case however, it either remained around twenty two

hours or got even longer, simply out of choice. Up to

a point, the longer the firing cycle the better. Speaking

purely in terms of efficiency, I could fire the kiln in

fifteen hours using a single cord of wood. Why then

would I fire for twenty four hours using two cords of

wood and lose twice as much sweat in the process?

Initially I was obsessed with the effect of ash. I still am,

but that is not all. Between 920oC. and 1250oC. one is

merely setting things up and getting the clay body into a

state where it is technically 'correct'. There is plenty of

ash on the pots but it has not fused, and has only settled

where it will not fall off. Between 1250oC. and 1300oC.

the surface of the clay body becomes sticky and specks

of ash will adhere and fuse spontaneously. It is also at

this point that the flame is at its most dynamic because

the clay surface can more readily respond. Thus it is

inevitable that at some point a long soak is desirable. 1

found it best to soak short of maximum temperature

rather than soaking for a long period at maximum

temperature, I did use some glazes, and this tended to

produce effects concurrent with overfiring.

Initially I would reach 1300oC. and then carry on

firing, soaking the kiln with filthy kiln atmospheres until

such a time as I felt it right to finish, or physical

limitations made it a necessity. This inevitably resulted

in dull colouring of both clay and glaze, and those glazes

high in alkali and iron ran too far, resulting in a distinctly

overfired appearance. Hence I decided to soak forty

degrees short of top temperature for up to six hours,

varying the kiln atmosphere considerably. This is to

promote stark variations in body colour on the pots, a

method of firing similar to the Japanese technique

known as higawari-that of changing fire. I would then

fire slowly with a clean atmosphere up to 1300oC. This

resulted in a much improved firing cycle. Colours of

both glazes and bodies were much brighter, due to the

oxidised end to the firing, and because the end was

slow high clay, high feldspar glazes were not adversely

affected (because of their viscous nature, a rapid rise

usually results in excessive crawling).

CLAY BODY

| High iron | Old stoneware clays mixed with 10% china clay grog and feldspar sand | Coarse |

| High silica low iron | HVAR ballclay | Fine |

| Porcelainous | BBV 80 Nepheline syenite 20 | Vitreous |

GLAZE

| High lime, high iron | Ash glazes | Unstable |

| High clay, high feldspar | Shino types | Stable |

Most clay bodies low in iron will flash well. Very

pleasing dry flashing can be obtained with aluminous

bodies, a siliceous body will promote shiny flashing. I

have pots solely from HVAR ballclay, which with the

combination of ash and fluxed surface look as though

they have been salted. A good shino type glaze will have

a temperature tolerance of anything up to one hundred

degrees although it won't look the same at either end of

the scale. Ash glazes high in flux are a lot more sensitive

than this and thus have a rather more critical

temperature range.

Advantages of using a pyrometer are few, cones are

a much better idea. A pyrometer is beneficial when

learning to fire, it is easy to see whether temperature is

rising or falling, and subsequently to discover why.

Every kiln is individual, and the only way to determine

the right way to fire it is through experience,

experimentation and some calculated guesswork. A

pyrometer may reduce a lot of this work, for it is easy to

see from it the results. What a particular action

provokes.

The pyrometer is however not only sensitive to overall

kiln temperature, but also to flame temperature. The

needle is fairly stable up to eleven hundred after which it

will rise and fall like a yo-yo. A hot oxidising flame will

send the needle rocketing thirty degrees or more, while

a relatively cold, yet violent reducing flame will cause it

to fall. It is so easy to become glued to the needle to the

point of neurosis. With a little experience it is easy

enough to see and feel the rise in accumulated heat.

There will come a point where the pyrometer can be

thrown away and senses relied on entirely, for with a

little practice they are far more sensitive than that

wretched figment of technology.

I found it necessary to start heavy reduction quite

early on, around 920oC. This could then be eased off

after 1100oC., decreasing up to 1260oC. To start much

later than 920oC. resulted in pale, anaemic looking

pots. An hours soak at 800oC. would ensure that all

carbon was burnt off, thus preventing any tendency to

bloat through carbon trapping later on. The kiln would

always stick for two hours or so around ten fifty for no

apparent reason. There are two factors which may

account for this. At some point the kiln structure itself

must reach a certain temperature for any further

internal atmospheric temperature to take place.

Secondly, the kiln is in the ground, and apart from being

a poor insulator, ground holds a large percentage of

water. This must be driven back to quite a considerable

depth before any further temperature rise is attainable.

It is this water content of the kiln that gives the pots

qualities that I believe cannot be achieved in any

conventional kiln. The simple fact that the kiln is dug out

of the ground will leave a distinct mark of individuality

upon the wares. This is usually borne out by subtle

colour variations of the clay body tending towards

pinks. I am also convinced that such stark contrasts of

colour in the clay body of any one pot cannot be

achieved with such effect in a conventiuonal kiln,

without the addition of some artificial means.

As a final note on technique, when I resolved to

wood fire, one reason for doing so was a growing

awareness of the overpowering nature of technological

gadgetry. I wanted to forget knobs, dials, gauges and

complicated firing cycles. However, unbeknown I was

immediately plunging into a self imposed system of pre

planned analysis and calculation, albeit without the

added sophistication of industrial elements. Instead of a

precision made venturi to control air intake, an old

house brick is used to plug up a hole between two more

old bricks. The principle is exactly the same, however it

is the latter method that is more in keeping with the

processes of the craft. If it were not for recording each

firing by means of an analytic graphing system,

reaching conclusions on how best to fire the kiln would

have taken much longer. Whether the method was true

to the means I am still undecided upon. Compromises

always have to be made, it is important that they are

always seen as temporary and eliminated one by one.

As potters we have a moral duty to provide an

education, something we have learned, to the

undiscerning eye of the public at large, for they are so

easily influenced by the wrong things. The question one

then might raise is, how do we convince them that wood

fired; coarse textured pots with ash all over them and

running or crawling glazes are good, and they should

buy them? The answer is that we don't. It is not just a

case of making money, it is a case of making pots. I

make pots because it is my job and I enjoy making them.

Pots made, my job is done, it is then up to others to

decide upon them by whatever criteria they choose to

use. However, as far as the maker is concerned they

must be made in a manner true to his own beliefs, and

hopefully struggling towards his own astronomically

sacrifices and effort, with all sorts of categorical

high standards. One can go to all sorts of lengths and

attitudes, but at the end of it all one has to judge

everything on the pots, that is what it is all about. The

look at, rarely do they consider the processes by which

pots are the final statement, it is the pots that people

they have been made. The craftsman has to provide his

contribution, no matter what magnitude he feels it

represents, and thus bring a little joy into someone's

home, and hopefully at the same time make a little profit

from love.

Patrick Sargent kiln design

Patrick Sargent

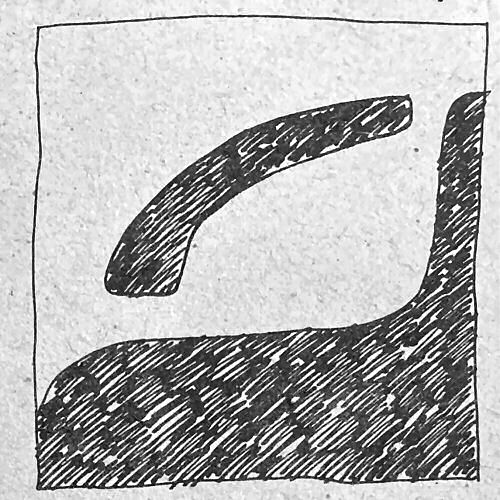

Anagama kiln shape

Patrick Sargent

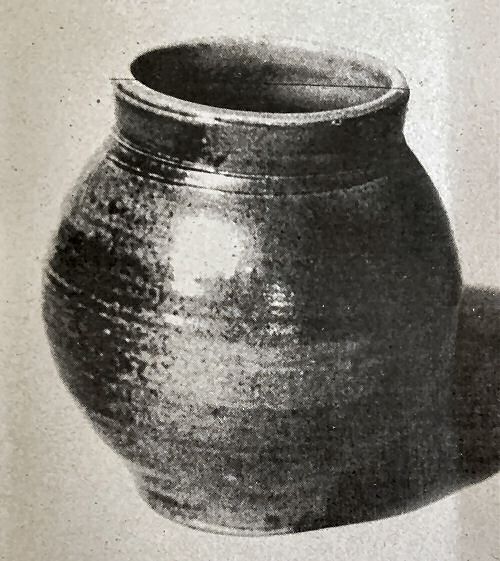

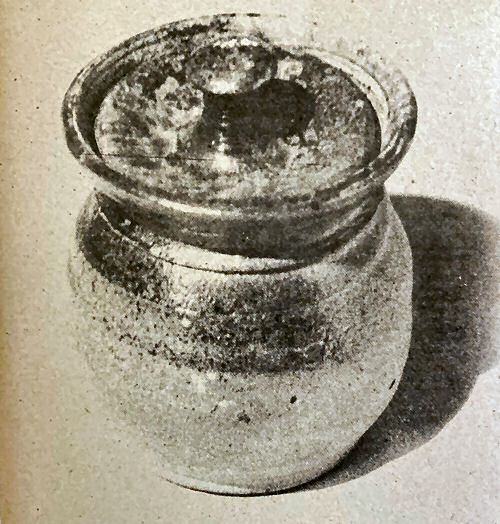

Unglazed jar, fired to 1300oC, glazed by flame and ash

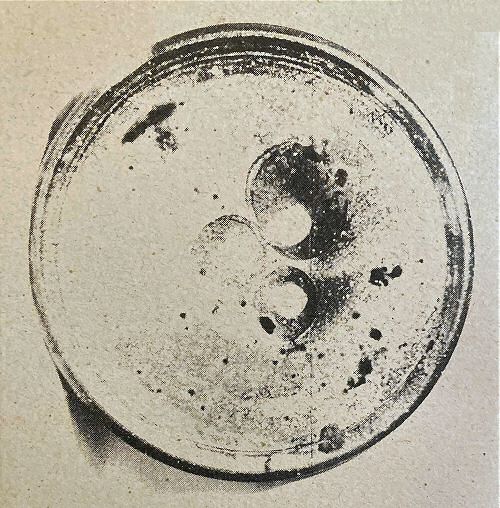

18" shino glazed plate

10" dish, shino glazed, ashing from wood

Unglazed jam jar

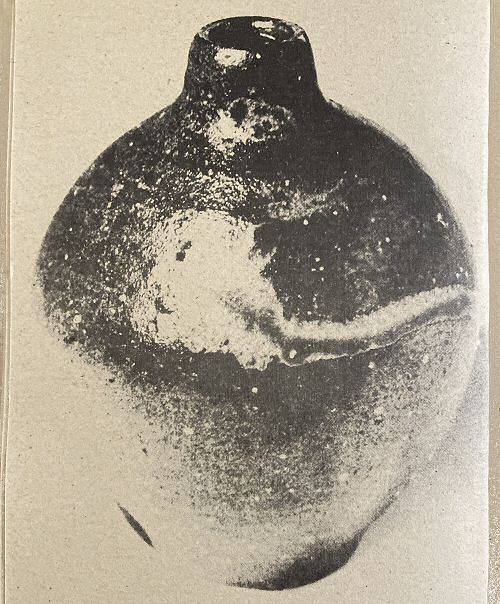

Unglazed 5" bottle, ashing has run down side, flecking from feldspar particles

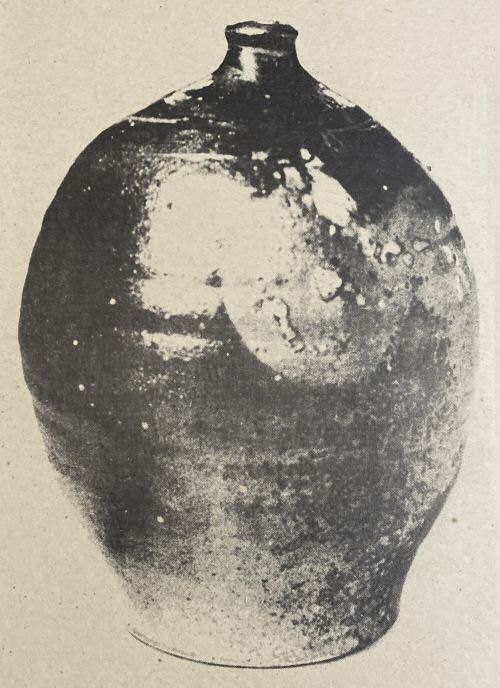

18" unglazed jar, flashing from firing caused by touching other pots

15" unglazed bottle, circles caused by bowls placed on pot which was fired on its side

8" shino glazed teapot, fired to 1330oC

6" shino glazed bowl, wax resist, chrome green dots, ashing

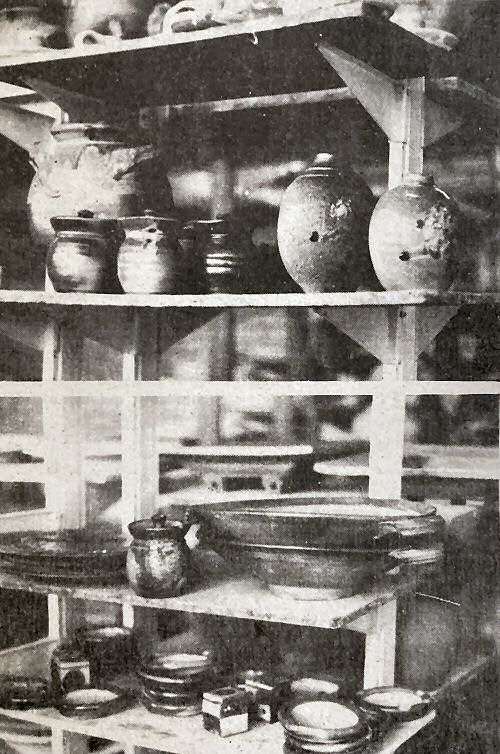

Fired pots